A Guide to the Different Types of Solar Panels

A solar panel is a device that converts solar radiation energy directly into electrical energy. So far, more than 100 different materials, structures, applications, and forms of solar cells have been researched. However, silicon is currently the most used material for solar cells. It can be classified into four types according to the substrate: monocrystalline silicon solar panels, polycrystalline silicon solar panels, amorphous silicon (a-Si) solar panels, and microcrystalline silicon (uc-Si) solar panels.

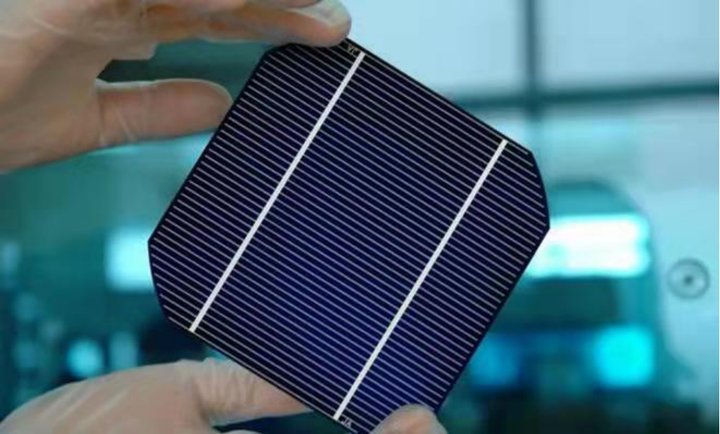

Monocrystalline Silicon Solar Panels

Monocrystalline cells are mostly rounded 125*125mm, with a dark blue surface, high color purity, black color after lamination with glass, and slightly higher conversion efficiency than polycrystalline. Monocrystalline solar cells are solar panels manufactured using single-crystal silicon wafers, the earliest developed and most mature technology. Monocrystalline solar panels have stable performance and high conversion efficiency compared to other types of cells, and the current industry average large-scale production of commercial cells is about 21.5% efficiency. The highest efficiency of large monocrystalline silicon cells is currently 26.6%, developed by Japan’s KANEKA in 2017.

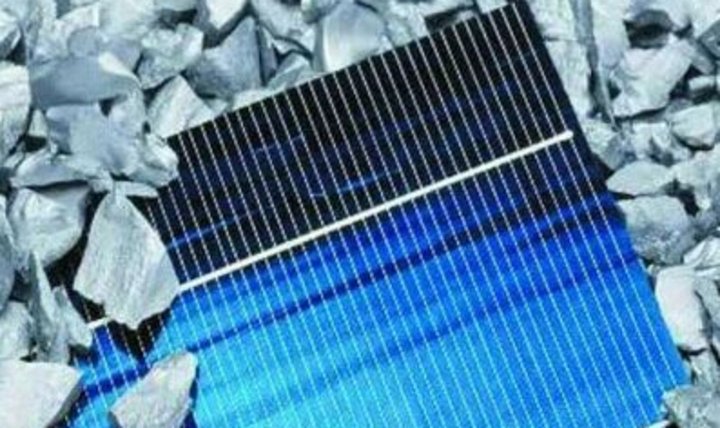

Polycrystalline Silicon Solar Panels

Polycrystalline silicon wafers are mainly 125mm x 125mm and 156mm x 156mm, two specifications, the surface is light blue, low color purity, and after lamination with glass, shows blue. When making polycrystalline silicon solar panels, the high-purity silicon used as raw material is not drawn into a single product but post-cast into a crystalline silicon ingot, then cut into thin slices using a cutting machine and then processed into cells.

Polycrystalline silicon wafers have distinct polycrystalline characteristics compared to monocrystalline silicon wafers with a single-grain shape on the surface. In contrast, monocrystalline silicon wafers have a uniform color on the surface.

Because the silicon wafer is composed of multiple different sizes and orientations of the grain, and thus the conversion efficiency of polycrystalline silicon solar panels than monocrystalline silicon solar panels, large-scale production of commercial polycrystalline silicon solar panels conversion efficiency of seven to 16% to 19%.

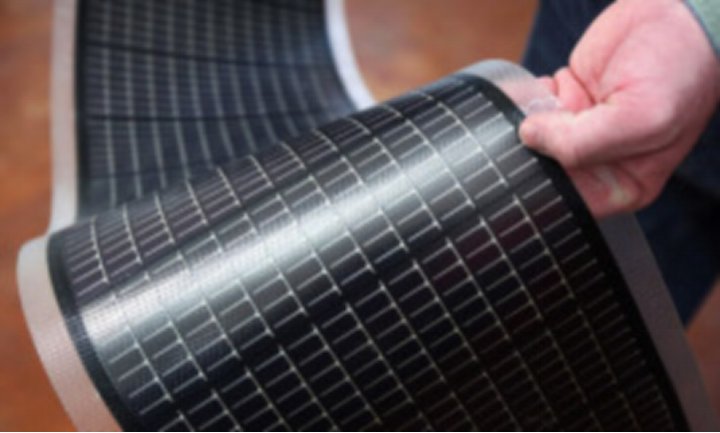

Amorphous Silicon (A-Si) Solar Panels

The thickness of an amorphous silicon solar panel is less than lum, less than 1/100 of the thickness of a crystalline silicon solar panel, which can save the supply of silicon material and significantly reduce manufacturing costs. In addition, because the temperature of decomposition and deposition is relatively low (about 200℃), the energy consumption during production is low, and the cost is relatively low.

The single cell area can be extensive (e.g., 0.5mx1.0m). In the visible range of the solar spectrum, the absorption coefficient of amorphous silicon is nearly an order of magnitude greater than that of crystalline silicon. Therefore, the peak of the spectral response of amorphous silicon solar panels is very close to the peak of the solar spectrum. Because of the large intrinsic absorption coefficient of amorphous silicon materials, amorphous silicon solar panels can generate much more power in weak light than crystalline silicon solar panels.

However, the efficiency of amorphous silicon solar panels is relatively low, and the conversion efficiency of commercial amorphous silicon cells produced on a large scale is mostly 6% to 10%. The photoelectric conversion efficiency of amorphous silicon solar cells will decay with the continuation of light time, known as the photogenic recession effect, resulting in unstable battery performance and short service life.

Microcrystalline Silicon (Uc-Si) Solar Panels

To obtain high efficiency and high stability of silicon-based thin film solar panels, in recent years and the emergence of microcrystalline thin film silicon solar panels, microcrystalline silicon can be prepared at low temperatures close to room temperature, especially the use of large amounts of hydrogen diluted silane, can generate grain size 10nm microcrystalline silicon film, film thickness a general in 2 ~ 3um.

By the mid-1990s, the highest efficiency of microcrystalline silicon cells had exceeded that of amorphous silicon, reaching more than 10%, and there was no photorecession effect. Still, it had yet to reach the level of large-scale industrial production. Now has been put into practical application to amorphous silicon solar cells as the top layer and microcrystalline silicon solar panels as the bottom layer of the (sipe – S5) stacked solar panels. The current conversion efficiency of microcrystalline silicon (B,=1eV) and amorphous silicon (E.=1.7eV) has exceeded 14, showing good prospects for application.

However, due to the thin limit of micromorphous silicon combined with a large number of amorphous silicon so can not be formed directly as monocrystalline silicon PAN junction surface must be micro into PIN junction; therefore, is the key to improve further the conversion efficiency of microcrystalline silicon solar cells in the future.

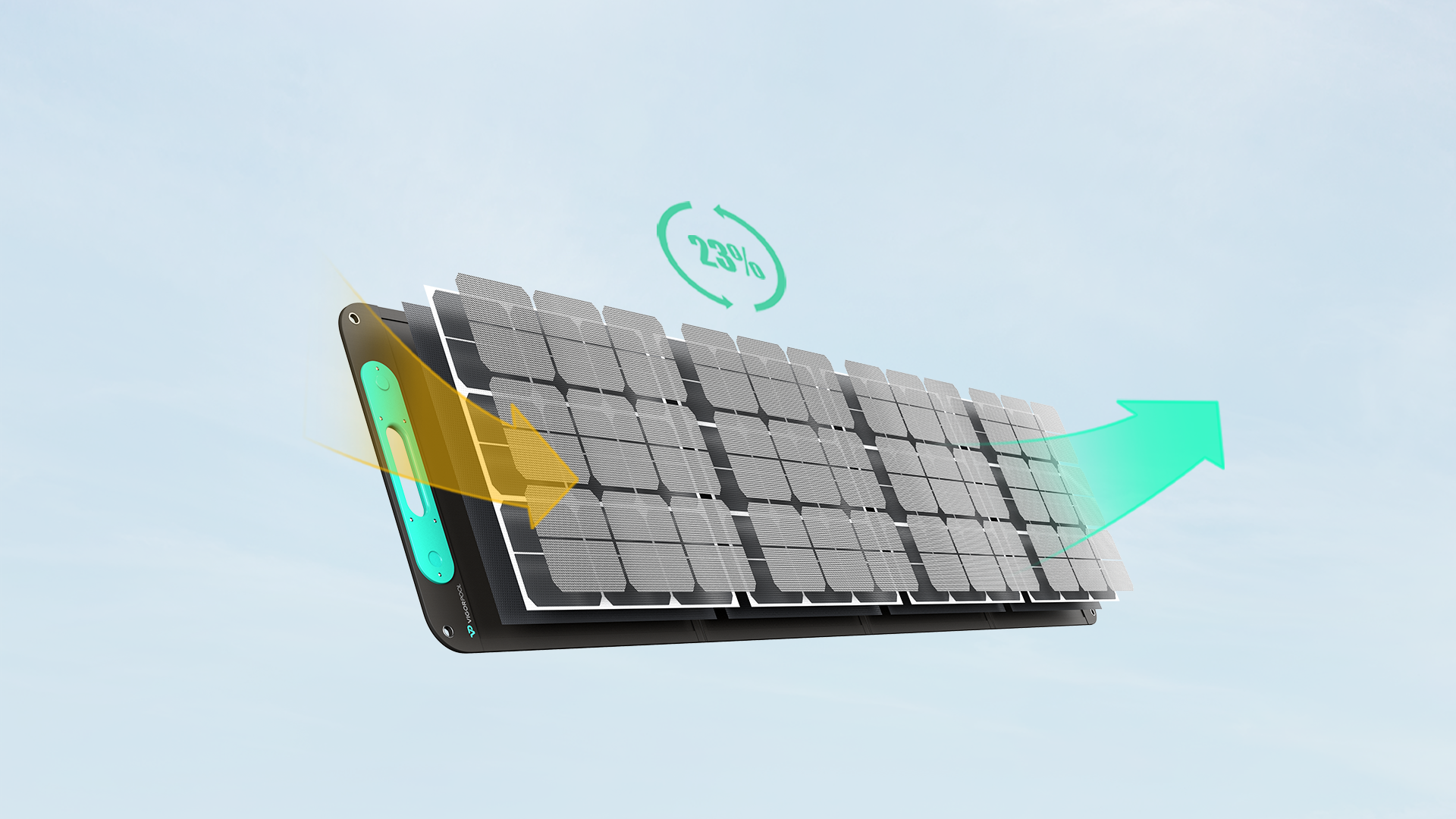

Vigorpool solar panels are made of high-efficiency monocrystalline silicon solar cells with a conversion rate of ≥23%. The unique wrapping technology allows the entire solar panel to perform conversion capabilities in various environments and to withstand the inevitable scratches, drops, rain, wind, and sand under natural environmental use. Vigorpool solar panels are available in multiple outputs, 100 W, 200 W, and 400 W. You can build a portable solar generator system for your home or outdoor trip by combining Vigorpool’s solar generator and solar panels.

In Conclusion

Understanding the many types of solar panels and the current technological developments helps us to choose the most efficient and suitable solar panels for our needs. When faced with the problem of building an excellent solar power generation system that suits our needs, the most important thing is how to make the system meet the actual electricity needs and how long the system will last. The more stable the system’s performance, the longer the use time, for the long-term users is the most cost-effective and experienced.